Three-axle three-way tipper

Back

THE VERSATILE FLIEGL THREE-WAY TIPPER IS A TRUE ALL-ROUNDER FOR YOUR BUSINESS

Tippers manufactured by Fliegl Agrartechnik are known and loved throughout the world. Thanks to the many different sizes and designs, we have models to suit all requirements. The three-way tippers are produced at our plant in Mühldorf and are characterised by their extremely robust construction and high-quality finish. The galvanised frame in particular is unique to Fliegl tippers. All bridge frames are manufactured and painted with high-quality materials.

Single-axle three-way tipper EDK 20 to EDK 80-4500

2,2 t0 8 t Single-Axle

Single-axle three-way tippers are characterised by their low net weight. However, they are still extremely robust and torsion-resistant. Their low centre of gravity makes them perfect for use on inclines. Outstanding stability, combined with excel- lent manoeuvrability and a high tipping angle are the hallmarks of the single-axle three-way tippers.

Low centre of gravity – great on sloping ground

Permitted total weight of 2200 to 8000 kg

Two-axle three-way tipper DK 60 to DK 180 XL

6 to 18 t Two-axle

Two-axle three-way tippers feature a galvanised, continuously shaped frame made from high-quality fine-grain steel. The low net weight and clever construction ensure a high payload. The heavy-duty truck slewing ring on the larger models highlights the robustness of the vehicle.

Heavy-duty suspension

Permitted total weight of 6000 to 18,000 kg

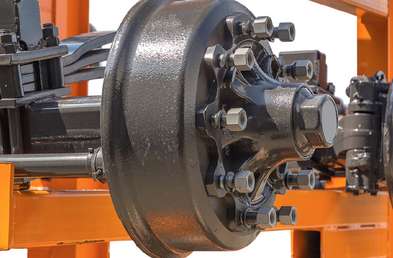

Three-axle three-way tipper DDK 240 6200 mm to DDK 310

24 to 31 t Three-Axle

The three-axle models are the kings of the three-way tipper range. A high payload combined with a permitted total weight of up to 31 tonnes deliver powerful performance. The bridge is made from high-strength steel, which has been sandblasted, dip-primed and coated with two-component lacquer.

ALB

Permitted total weight of 24,000 to 31,000 kg

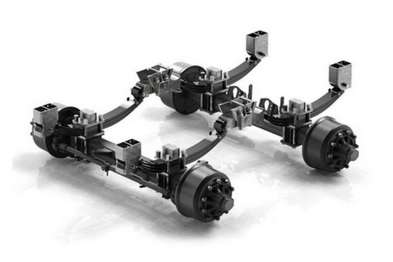

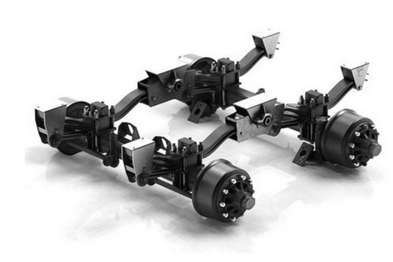

Tandem three-way tipper

TDK 80-88 4000 mm to TDK 255 Profi

8 to 20 t Tandem

Tandem three-way tippers boast outstanding stability during any transport thanks to their extra-large axle track, low Platform height and tandem chassis. A tipping angle of up to 55° allows for clean and complete emptying of all bulk materials. The galvanised hollow section frame ensures torsional rigidity.

Conical bridge as of 4500 mm bridge length

Permitted total weight of 8000 to 20,000 kg

-

Durable and robust

- Sturdy, galvanised hollow section frame

- Powder-coated side panels starting from EDK 40

- Bridge made from highly wear-resistant steel

- High-quality materials

- Constructed in Mühldorf

-

Maximum stability

- Low centre of gravity

- Extra-wide track

- Compact design

-

Simply practical

- High tipping angle

- Extremely manoeuvrable

- Low net weight

-

Highly versatile

- Three-way tipping function

- Available with side panel extensions

- Can be combined with additional trailers (not possible with EDK)

- Diverse equipment options

- Grain hatch standard on virtually all models

-

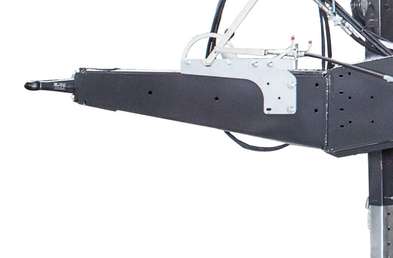

Hydraulic rear panel starting from TDK 80

- With the new locking system developed by Fliegl, the rear panel is raised vertically a little before swinging out.

- The hydraulic rear panel opens by approx. 90° to enable loading from the rear.

- The extra-large axle track guarantees outstanding stability on any terrain.

- Very low platform height

- Lateral side panels can be opened for loading