Slurry nutrient measurement

Slurry nutrient measurement

Prepared for the future with Fliegl!

The highest goal of a farmer is to provide the crops with optimal nutrients. The right choice of a suitable application rate is relevant not only for the application of mineral fertiliser but also for slurry application.

Here, the knowledge of the composition of the ingredients for a precise and efficient slurry application is of enormous importance. Nutrient samples that are measured by a laboratory are classified as a random sample and cannot characterise frequent nutrient fluctuations within the slurry storage.

Fliegl offers you two systems with state-of-the-art technology to precisely determine their digestate nutrients even with heterogeneous substrates.

NIR station - NUtrient measure station

Innovative and practical! Two features that Fliegl has once again demonstrated with its own NIR station. Not only the farmer himself, but also ever stricter legal requirements demand exact insight into the ingredients of the slurry. Together with the Harvest Lab 3000 NIR sensor, the Fliegl flowmeter forms the heart of the station.

After completing the measurement, you can conveniently view the analysed nutrient values on your laptop or tablet. Numerous mounting options for transport and a compact design guarantee a high level of mobility.

Nutrient measurement at the tank (slurry sensing)

Compared to the principle of a stationary measuring unit, the output of the manure sensing (at the tank) does not depend on average values but on real measured values. A part surface specific application can therefore be carried out easily. With manure sensing, you know exactly how much kg of which nutrient has been applied per hectare.

-

Convenient documentation of nutrients

-

Settlement of slurry can be achieved via nutrient content (nutrient exchanges)

-

Measurement of total nitrogen (Nt), ammonium nitrogen (NH4-N), phosphate (P2O5), potash (K2O) and TS content in real time

-

Accurate determination of nutrients even in highly heterogeneous slurry

-

Recognition of NIR technology (Harvestlab 3000 by John Deere) for documentation

(depending on the regional state) -

Increase nutrient efficiency through optimal application rates

-

Better estimation of yield efficiency through organic fertilisation (mineral fertiliser equivalent)

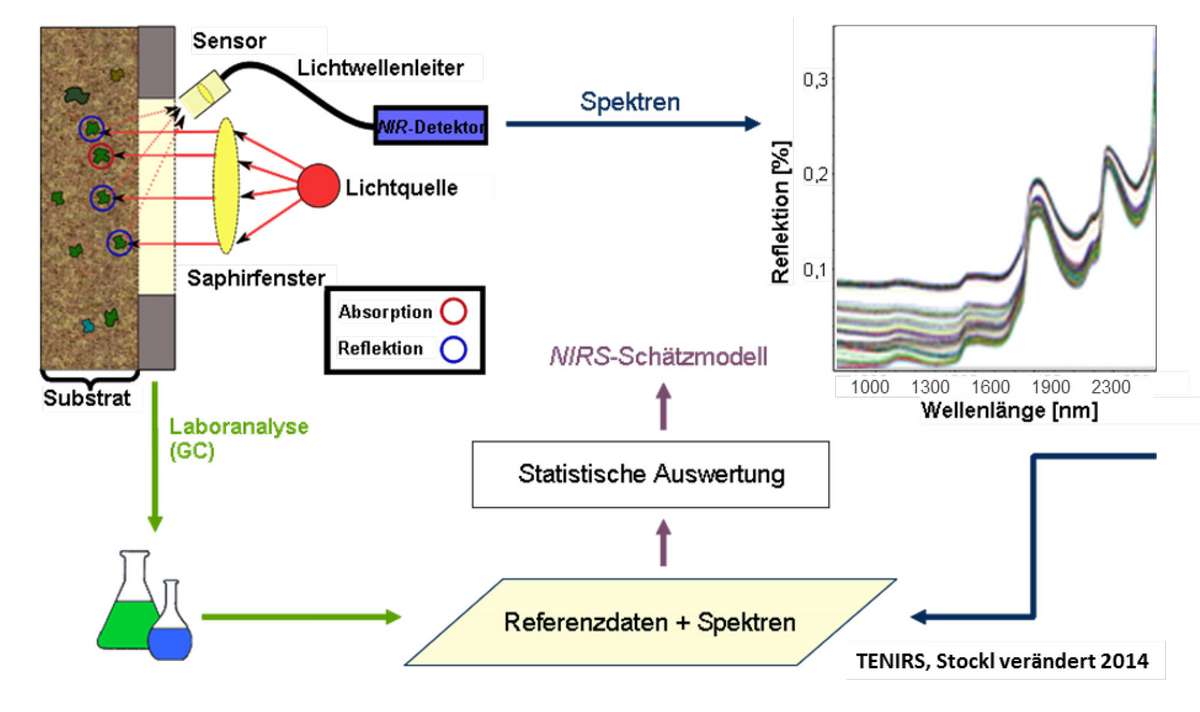

Functional principle nutrient measurement with near-infrared spectroscopy (NIRS)

So that the nutrient quantities can be exactly recorded during the measurement, the current slurry flow is determined with the help of the Fliegl flow meter.

The measuring head of the NIR sensor follows immediately. As the slurry flows past, light is blasted into the slurry stream by the NIR sensor. At the same time, the reflected light can be resumed and evaluated. The intensity of the resulting light wavelengths reflects the content of the various ingredients. Light spectrum is evaluated with the help of calibration values. The data is processed by the control unit and displayed digitally to the farmer.

Equipped for the John Deere Harvestlab 3000

The Fliegl nutrient measurement systems are prepared for this sensor.

John Deere Harvestlab 3000 approved for nutrient documentation (depending on the regional state)

HarvestLab™ 3000 uses Near-InfraRed (NIR) spectroscopy to determine the various constituents present in harvest, silage or slurry materials, in less than a second.

The new HarvestLab™ 3000 hardware is state-of-the-art technology and is based on millions of hours of farmland experience. With its 12% broader

wavelength spectrum, it achieves greater accuracy and provides more than 4,000 measurement points per second. You are not just given the result of a random sample check,

but statistically reliable data in real time.