Hochdruckfässer HFW

HIGH PRESSURE TANK HFW

The ideal solution for farms with external filling

Capacity: 5,000 l to 27,500 l

The Fliegl high pressure tanks are the perfect solution for farms or groups of farms who want to fill their tank with the help of a stationary pump. The HFW tank offers you a simple and robust technique with an enormous output. Equipped with the proven centrifugal pump from Battioni, discharge rates of up to 6,500 l / min can be achieved. The standard push cover, which is hydraulically opened and closed, allows for clear and comfortable filling. The distribution accuracy is ensured even with large working widths by the high pressure pump system.

MAXX LINE HIGH PRESSURE TANK

14,000 TO 18,000 l

The Maxx Line Plus high-pressure drums convince with standard large-volume tires 750/60 R 30.5. These deliver maximum comfort both on the field and on the road, and also provide optimum protection against soil compaction. Slurry spreaders with working widths up to 24 meters can be supplied with liquid slurry with the powerful centrifugal pump.

The all-rounder for farmers who prefer their own equipment

MAXX LINE HIGH PRESSURE TANK

14,000 TO 18,000 l

The Maxx Line Plus high-pressure drums convince with standard large-volume tires 750/60 R 30.5. These deliver maximum comfort both on the field and on the road, and also provide optimum protection against soil compaction. Slurry spreaders with working widths up to 24 meters can be supplied with liquid slurry with the powerful centrifugal pump.

The all-rounder for farmers who prefer their own equipment

POLY LINE HIGH PRESSURE TANK

6,000 TO 18,500 l

The POLY Line tanks impress with their low net weight. The container is proudly made in Germany from glass fibre reinforced plastic. Simple cleaning, a high payload and long service life are the hallmarks of this system. An optional Telescopic axle not only reduces ground pressure but also ensures safe working on steep slopes.

Slurry application made easy

| SINGLE-AXLE | TANDEM |

-

High flow rates

-

Very robust and simple pump technology

-

Not susceptible to foreign bodies

-

Can be combined with any Fliegl slurry spreader regardless of the working width

-

Low maintenance with long running times

-

Accurate and variable slurry spreading

-

Comfortable handling with optimum weight distribution

-

Low net weight

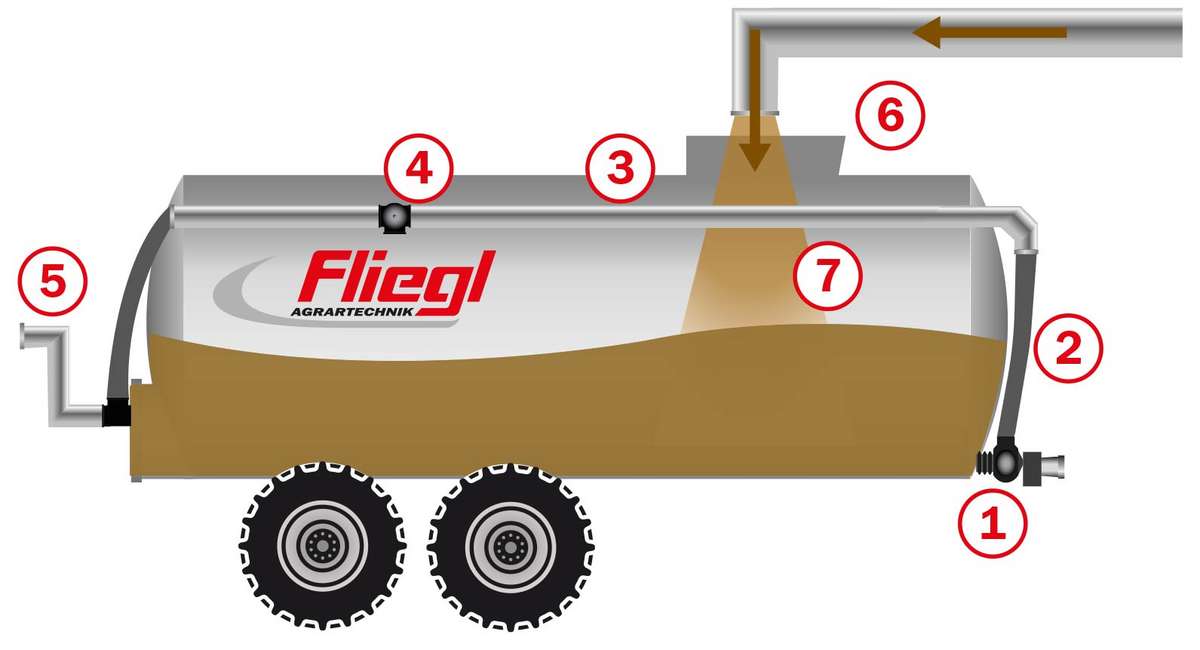

Filling

The high pressure tank cannot provide suction on its own since the built-in centrifugal pump is only responsible for spreading the slurry.

In order to fill, an external pump is needed.

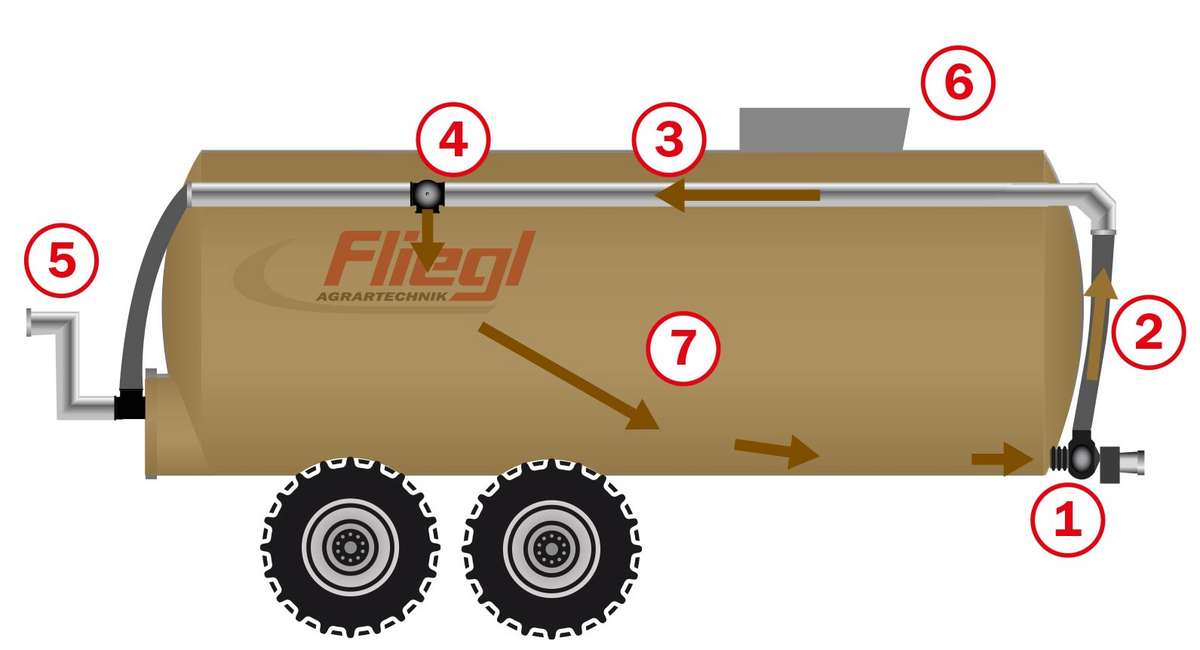

Stirring function (optional)

The slurry can be circulated via the stirring function (flushing line). The slurry is sucked from the front area of the tank and routed back into the tank via the pressure line and the optional three-way valve.

Discharge

The slurry is removed from the front of the tank and pushed back to the spreader via the pressure line.