Slurry nutrient measurement

Nutrient measurement at the tank (manure sensing)

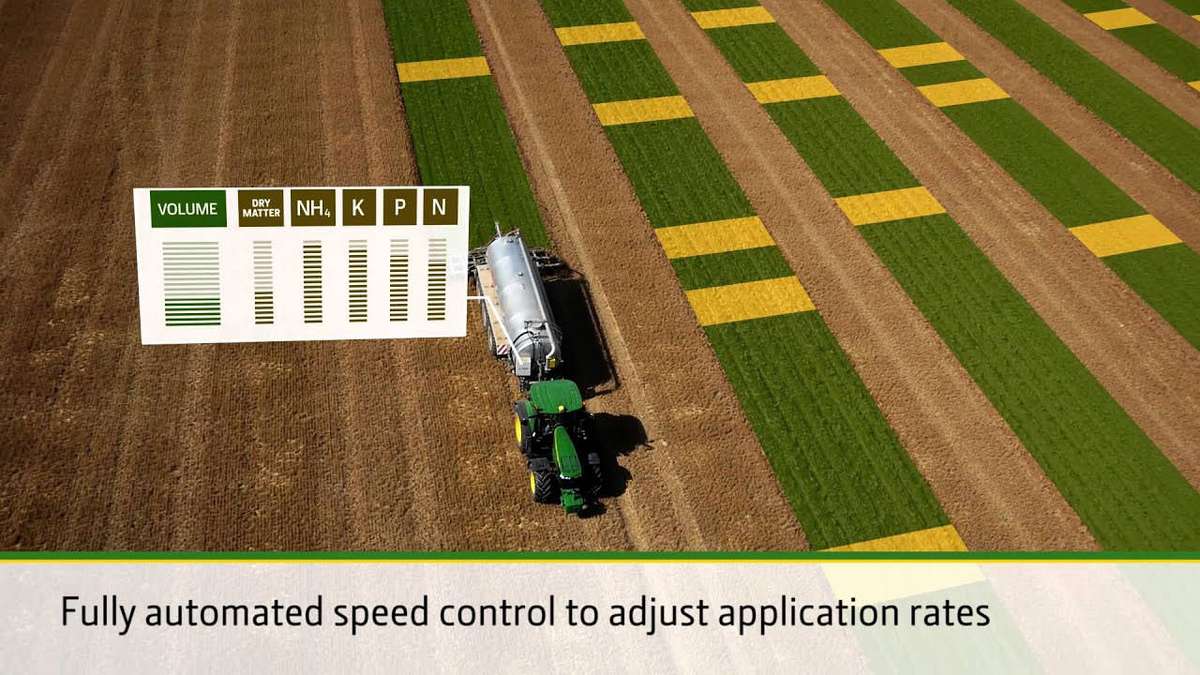

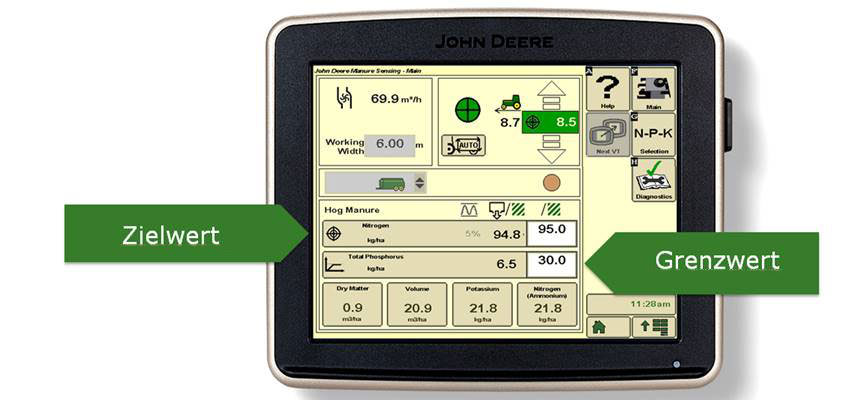

Since the nutrient distribution of the slurry is often very heterogeneous, the choice of the correct application rate is a considerable challenge, which you can master with ease with manure sensing. The ingenious system helps to not only measure nutrients in real time in front of the slurry applicator, but also determine the flow rate with the proven Fliegl Flow Control. The application rate can be adjusted immediately due to a change in the nutrient concentration.

Compared to the principle of a stationary measuring unit, the output of the manure sensing (at the tank) does not depend on average values but on real measured values. A part surface specific application can therefore be carried out easily. With manure sensing, you know exactly how much kg of which nutrient has been applied per hectare.

What distinguishes manure sensing on the tank?

- Real-time measurement of N, P, K, NH4, dry mass and volume, immediately in front of the applicator

- In combination with the proven John Deere HarvestLab 3000 sensor

- Demand-oriented and precise application

- Utilises the entire nutrient potential of the slurry while at the same time complying with statutory regulations.

- Yields and product quality are maximised while reducing the costs for mineral fertilisers

- Automatic speed adjustment of the tractor (only with John Deere tractors with ISOBUS Class 3)

- Documentation: Volume applied, nutrients applied (total per field and specific sub-areas)

- Maximum control range and fast response through variable speed and – in the second instance –

- adjustment of the flow rate through the Fliegl Flow Control

- Partial surface slurry application available based on the nutrients

You can find more information on this topic in this video: