PFW pump tank

PFW pump tank

The perfect technology for high-power suction and application

Capacity: 6,200 l to 27,500 l

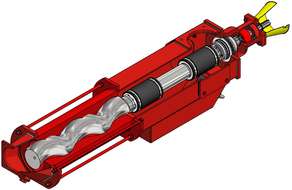

Fliegl pump tanks offer a perfect blend of quality, power and practicality. The outstanding features and equipment, which are the result of decades of experience in the field of pump tank technology, ensure professional slurry application at all times. The name Fliegl stands for maximum diversity in the world of vehicle construction, and this is also reflected in our pump tank product range. Be it a steel tank or a model made from glass fibre reinforced plastic – our extensive portfolio allows us to address all your needs and provide solutions to suit your exact requirements. With regard to the pump technology, you can choose between an eccentric screw pump or a rotary piston pump.

MAXX LINE PUMP TANK

6,200 TO 25,000 l SINGLE-AXLE, TANDEM, TRIDEM

The tanks of the Maxx Line tanks offer bespoke equipment and are characterised by their robust construction. Another benefit of the Maxx Line tanks is the wide choice of container sizes. The tanks are compatible with all slurry spreading devices.

Wide choice of capacities

| all variations |

MAXX LINE PLUS PUMP TANK

12,000 TO 20,000 l TANDEM

As an enhancement of the Maxx Line, the Maxx Line Plus impresses with its standard high-volume tyres. These not only deliver maximum comfort both on the field and on the road, but also provide optimum protection against soil compaction. Powerful and convenient suction is ensured by an optional suction nozzle combined with a powerful eccentric screw pump.

The all-rounder for farmers who prefer their own equipment

DUO LINE PLUS

12.000 l to 18.000 l TANDEM

A particular feature of PFW Duo Line Plus is that the tank is split into two chambers. However, an opening in the separating wall allows the slurry in the lower part of the tank to flow from one section into the other. During filling, the air regulation via the vent valve ensures that the slurry level rises evenly in both chambers. During discharge, the air regulation has the opposite effect: In this case, the rear chamber is emptied first while the slurry in the front chamber is held back. The weight is thus shifted to the front. This ensures an ideal drawbar load at the rear of the tractor when travelling uphill. Residual emptying takes place once the slurry volume in the rear chamber has dropped to a level that allows air to enter the front chamber via the separating wall.

Permanent drawbar load at rear of tractor – perfect for inclines

JUMBO LINE PLUS PUMP TANK

14,000 TO 18,000 l TANDEM

Thanks to the Boogie SB floating assembly and in combination with 30.5" wheels, the JUMBO Line Plus tanks ensure safe and soil-friendly operation on sloping surfaces. The special feature of these tanks is the variable adjustment of the drawbar load at the rear of the tractor, which is enabled by the hydraulically adjustable axle assembly. The result is improved traction and greater pulling power for your tractor.

The hill specialists for stable handling

POLY LINE PUMP TANK

6,000 TO 18,500 l SINGLE-AXLE, TANDEM

The POLY Line tanks impress with their low net weight. The container is proudly made in Germany from glass fibre reinforced plastic. Simple cleaning, a high payload and long service life are the hallmarks of this system. An optional telescopic axle not only reduces ground pressure but also ensures safe working on steep slopes.

Slurry application made easy

| ALL VARIATIONS |

POLY LINE PLUS PUMP TANK

12,500 TO 18,500 l TANDEM

As an enhancement of the Poly Line, the Poly Line Plus impresses with its standard high-volume tyres. These not only deliver maximum comfort both on the field and on the road, but also provide optimum protection against soil compaction. Powerful and convenient suction is ensured by an optional suction nozzle combined with a powerful eccentric screw pump.

Slurry application made easy

| ALL VARIATIONS |

ALPHA LINE PUMP TANK

10,600 TO 27,500 l SINGLE-AXLE, TANDEM, TRIDEM

The Alpha Line slurry tank was designed especially for intensive, professional use. It features an extensive range of standard equipment, which can be supplemented with clever and sophisticated technical details – with a particular focus on "smart farming". This tank series offers a number of interesting options when it comes to soil protection.

Maximum equipment levels for professional use with outstanding performance

| ALL VARIATIONS |

TWIST LINE PUMP TANK

13.000 L SINGLE-AXLE

The Fliegl TWIST LINE is a high-tech tank, which is not only gentle on the soil but also impresses with its outstanding manoeuvrability – even on the headland.

Thanks to the central mounting, the axle of the single-axle tank can be rotated by approx. 11 degrees relative to the tank container to enable travel in crab steering mode. As a result, soil compaction is greatly reduced. As soon as the axle turns, the optional three-point hydraulics are swivelled accordingly, thus eliminating the need for an additional pivoting headstock for the attachment.

Maximum ground protection with utmost manoeuvrability

| all variations |

BIG FOOT TANDEM VACUUM TANK

16,000 TO 18,000 l TANDEM

Fitted with 800/65 R32 tyres as standard, the Fliegl BIG FOOT tank more than lives up to its name.

Particularly on wet and boggy ground, the tank enables effective slurry application with minimal ground pressure and optimum load distribution. Individual wheel arches tailored to the tyre dimensions are also integrated.

The hydraulic axle suspension ensures excellent ground adaptation combined with maximum ride comfort, even on steep slopes.

Massive tyres to protect your soil

-

High suction and spreading performance

-

Compatible with any Fliegl slurry spreader

-

Low noise emissions

-

Accurate and variable slurry spreading

-

Linear flow rate with constant PTO speed

-

Sophisticated pump technology

-

Comfortable handling with optimum weight distribution

-

Low centre of gravity for safe working on inclines

-

Low net weight

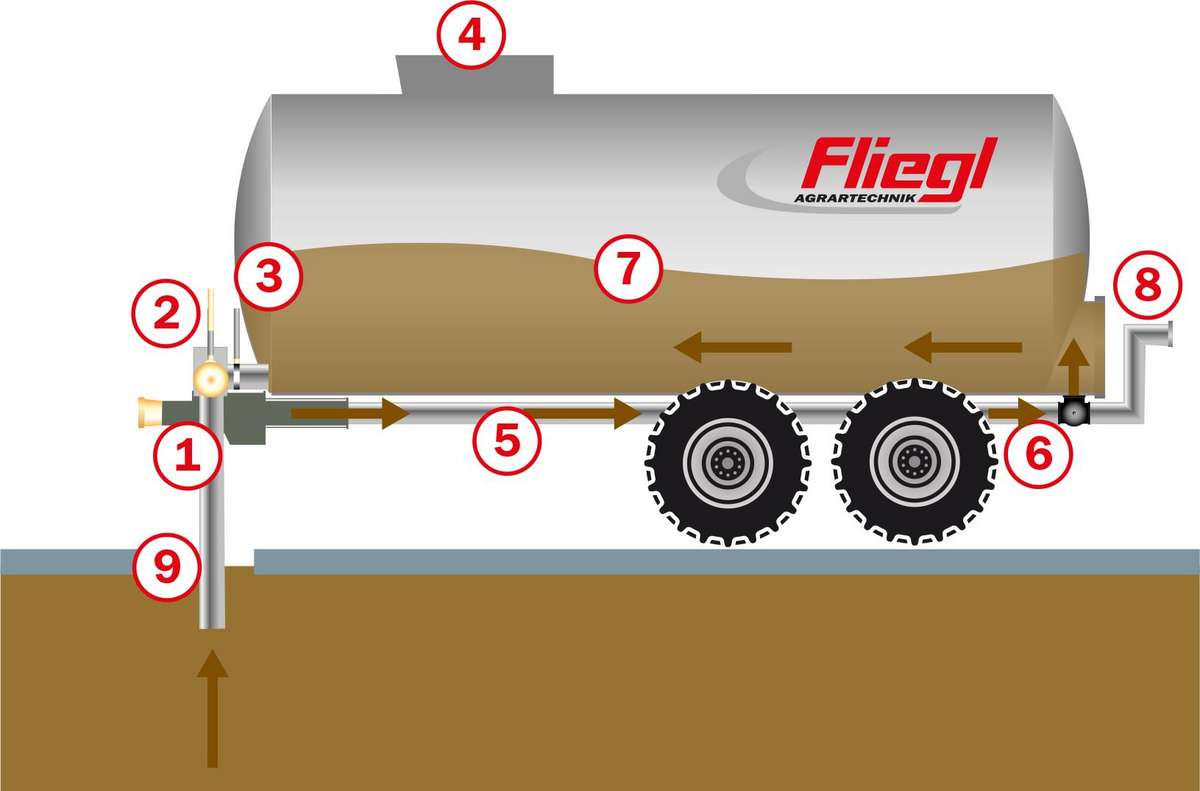

Suction

For the pump tank suction process, the pump gate valve must be closed and the suction gate valve must be opened. Due to the negative pressure generated by the eccentric screw pump, the slurry is sucked from the pit into the pump, which forces it back via the pressure line. When the three-way valve at the end of the slurry tank is in the correct position, the tank fills up from the rear.

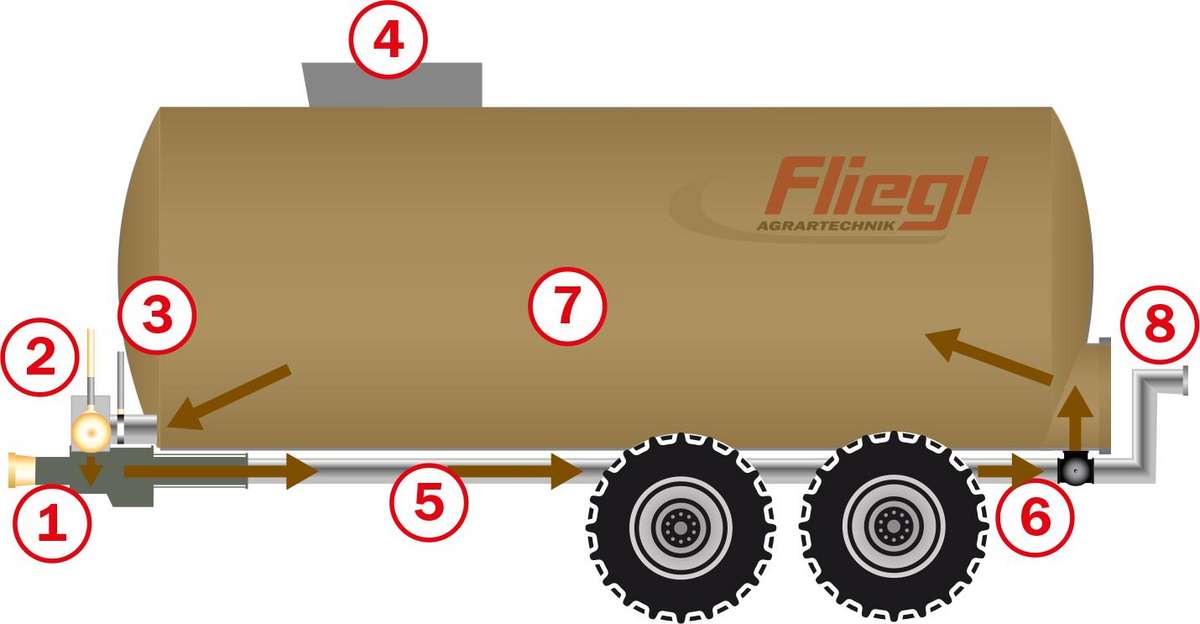

Stirring function

The slurry is circulated via the stirring function of the pump tank. This requires the suction gate valve to be closed and the pump gate valve to be opened. The slurry is sucked from the front area of the tank container and routed back into the tank via the pressure line and the three-way valve.

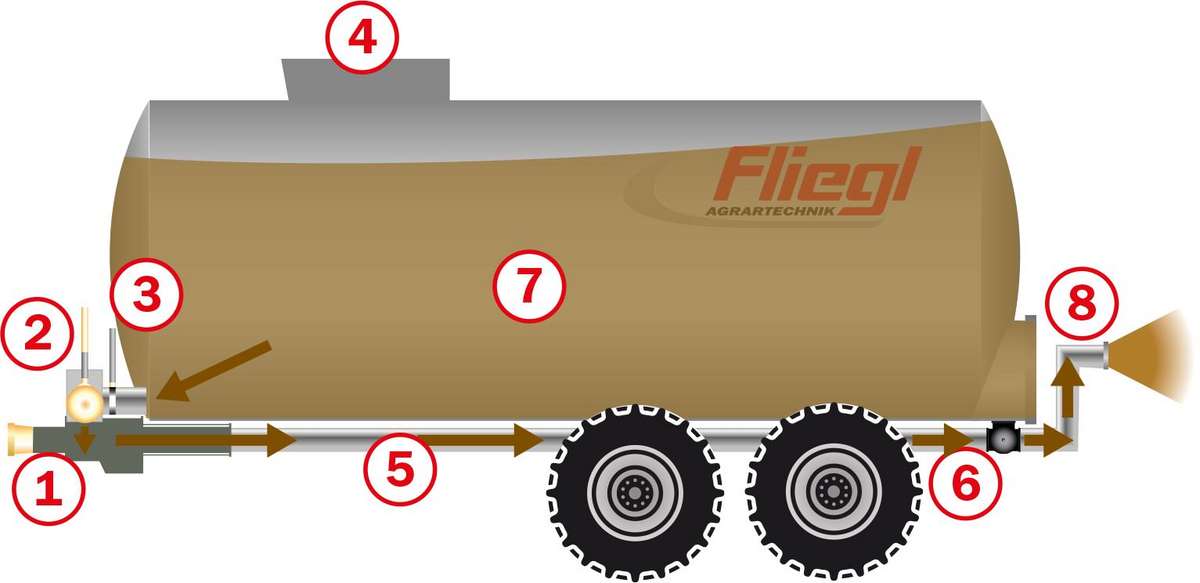

Discharge

To spread the slurry on the field and pump it out of the tank, the pump gate valve must be opened and the suction gate valve must be closed. The three-way valve must be open in the direction of the spreader. By means of a hole pattern on the hydraulic cylinder of the three-way valve, the discharge volume can be controlled manually and part of the slurry can be fed back into the tank.

* Equipment depends on the relevant tank series. Further details can be found in the Pump tank overview.