News & Dates

Fliegl‘s KDS 270 muck control now DLG APPROVED

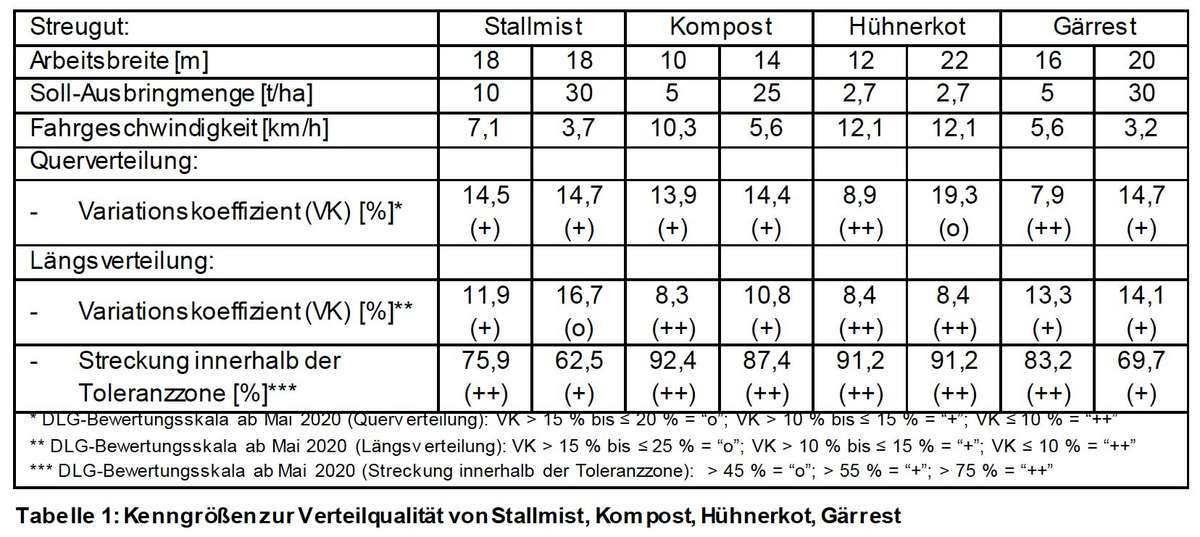

The coefficients of variation determined for evaluating the lateral distribution are below 20% for all four spreading materials and are evaluated as good (+) for manure and compost for both application rates. The lateral distribution of chicken manure is rated very good (++) at a working width of 12 meters and rated passed (o) at 22 meters. In the case of digestate, the lateral distribution is rated very good (++) for an application rate of 5 t / ha and the associated working width of 16 meters and good (+) for 30 t / ha and a working width of 20 meters.

These mostly very good and good results of the Fliegl KDS 270 muck control are honored by the DLG with the test mark DLG APPROVED.

Fliegl is proud to have manufactured a first-class product with the KDS 270 Muck Control and is pleased to be able to offer it to farmers and contractors.

In order to be able to fulfill the wishes of all customers, Fliegl now offers with its KDS not only the tried and tested push-off technology but also a scraper floor as the feeding technology. It consists of two chains with 140 chain links each. Each individual chain link has a breaking load of 50 t. The chains connect 41 continuously closed scraper floor strips. The scraper floor is driven hydraulically via a side gear and the speed can be continuously adjusted. If the chains lose their tension over time, a mechanical or optionally hydraulic chain tensioner ensures easy maintenance.

The loading area is separated from the spreading unit by a hydraulic feed control valve. In order to guarantee an optimal sealing, it has an internal frame guide. The opening position can be adjusted continuously on the control terminal. The driver conveniently receives information about the opening width of the gate valve via the fill level indicator on the front wall of the spreader.

Right after the feed control gate are two horizontal spreader rollers with a diameter of 770 mm each. These ensure optimal mixing, loosening and dosing of the spreading material. Easy maintenance is guaranteed by exchangeable blades. If something should spread inside, the system automatically switches off thanks to electronic speed monitoring when the roller speed is reduced.

The heart of the KDS 270 Muck Control is the VarioSPLASH disc spreading unit with two large spreading discs having a diameter of 1100 mm. Each spreading disc is made of wear-resistant HB 400 steel and equipped with six swiveling spreading vanes. Depending on the spreading material, individual settings can be made on the disc spreader. On the one hand, all blades can be manually adjusted to three different swivel angles. On the other hand, the point of application of the spreading material on the spreading discs can be varied using the spreading flap. The KDS can thus be optimally adapted to different circumstances.

The spreading rate is determined by the feeding rate of the scraper floor, the opening width of the gate and the driving speed of the tractor.

The entire spreading mechanism of the Fliegl KDS 270 Muck Control is driven by the PTO shaft via an oil bath gear. A special transfer case ensures an optimized distribution of power to the spreading discs and rollers.

For three days, tests were carried out on the company's own standardized test rig at the Mühldorf plant. For the DLG test, four spreading materials, dry chicken manure, digestate, manure and compost were examined in various amounts. The test is based on the DLG test framework "Spreader for organic solids", which had recently been tightened by 5% in all categories. Despite the stricter test criteria, the results are impressive:

The coefficients of variation determined for evaluating the lateral distribution are below 20% for all four spreading materials and are evaluated as good (+) for manure and compost for both application rates. The lateral distribution of chicken manure is rated very good (++) at a working width of 12 meters and rated passed (o) at 22 meters. In the case of digestate, the lateral distribution is rated very good (++) for an application rate of 5 t / ha and the associated working width of 16 meters and good (+) for 30 t / ha and a working width of 20 meters.

These mostly very good and good results of the Fliegl KDS 270 muck control are honored by the DLG with the test mark DLG APPROVED.

Fliegl is proud to have manufactured a first-class product with the KDS 270 Muck Control and is pleased to be able to offer it to farmers and contractors.